Capacity : ..

Head : ..

Working Temperature : ..

Casing Pressure (Pmax) : ..

PUMP DESIGN FEATURES

- It’s pretty suitable for using at movable (Up and Down) systems.

- They can be mounted easily with the help of AISI304 or AISI316 plate and bolt pin to the Stainless box section

- They can be also mounted to the HDPE, PVC or Steal Pipes with the help of saddle.

- Body and frame material of diffusers is (PP) polypropylene. And using 30% CFR (fiberglass) its production to increase the strength of the material to different chemicals and high temperatures and harmful UV rays

- The joint part of plate diffuser is manufactured for a saddle is 2’’ external grooved and for box section 30 mm (external outlet male).

- The membrane of plate diffusers are EPDM as standard. However, according to biological process it can be different as Silicon, PTFE (Teflon) covered.

- When the air flow is stopped, the gaps on the membrane close themselves because of its conic structure, in order to prevent the sludge and particulate matter fill.

- Maximum oxygen efficiency is aimed while different production techniques with carefully chosen materials.

- It warrants between 35%-45% oxygen efficiency.

- It holds energy costs very low because of minimum pressure loss.

- The aeration costs loom very large at total operation costs. Because of that reason, Aquaflex Plate Diffusers decrease the operation costs minimum.

|

Type of Product |

Total Height (mm) | Effective Area / Total Area (mm) | Perforated Area (m²) | Capacity (Nm³/h) | Material of Membrane | Total Weight (kg) |

Outlet |

|

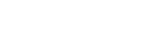

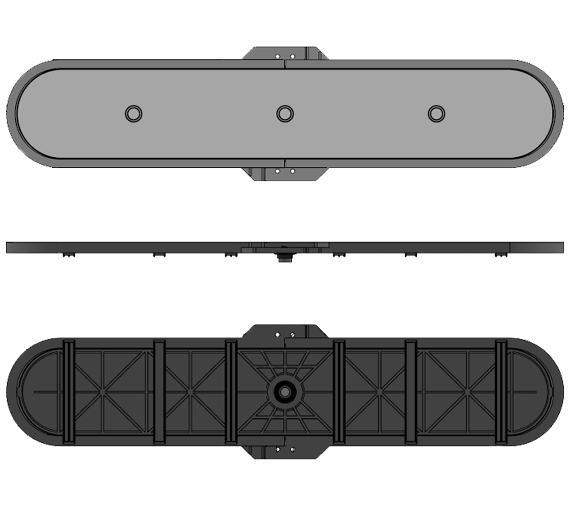

APD1100 Plate Diffuser |

61 | 185*1070/270*1105 | 0,2 | 2-25 | EPDM – Silicon – PTFE Coated | 3,5 |

2” or 30mm |

AQUAFLEX APD1100 PLATE DIFFUSER PUMP USAGE AREAS

Compared to other diffuser types, Aquaflex APD1100 Plate Diffuser has much higher air capacity and it has a larger surface area. It is usually preferred in plants which has high capacity. There are proper mounting options according to pipe or box sections. Aquaflex plate diffusers are manufactured with latest technology of present day and used at waste water treatment plants. The projection of each diffusers of Aquaflex was done after Research and Development studies that response the requests of waste water treatment plants. The materials of Aquaflex diffusers are chosen carefully according to processes of waste water treatment plant and coordinately check before delivery.