Capacity : ..

Head : ..

Working Temperature : ..

Casing Pressure (Pmax) : ..

PUMP DESIGN FEATURES

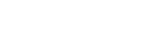

1.Effective and sustainable nutrient removal at with low nitrifying activity

2.Possible Anammox activity in biofilm reactor (MBBR) with realtime O2 control

3.Utilization of more carbon for biogas plants

4.Reduced aeration requirement (aeration for nitrification)

5.Easy upgrade to Membrane Bioreactor for reuse

|

Description |

Technical details |

|

Diameter of BioAQUA MBBR |

26 mm |

| Width of BioAQUA |

10 mm |

|

No of inner departments |

19 qty |

| Approximate dia. of inner deprt |

5 mm |

|

Surface Area of BIOAQUA MBBR |

650 m2/m3 |

| Material of BIOAQUA MBBR |

PE VIRGIN |

| Color of BIOAQUA MBBR |

Naturel |

AQUAFLEX BIOAQUA MBBR PUMP USAGE AREAS

The MBBR process is designed so that microorganisms create a multiple layers of biofilm on the surface of small plastic carriers – Aquaflex BioAQUA, floating in the reaction tank. Aquaflex BioAQUA was designed to have perfect contact with liquid in the tank and still providing the maximum surface for biofilm growth. Aquaflex BioAQUA plastic media carriers floats in liquid in the reactor and are kept in motion either by air injection aerobic system or by stirrers in anoxic or anaerobic systems. By moving evenly throughout the reactor Aquaflex BioAQUA provides oxygen that is needed for BOD removal and Nitrification and reduces the impurities in water as well as bulking of the sludge to minimum.